Manufacturing Facilities

State-of-the-art supply base answerable to market needs.

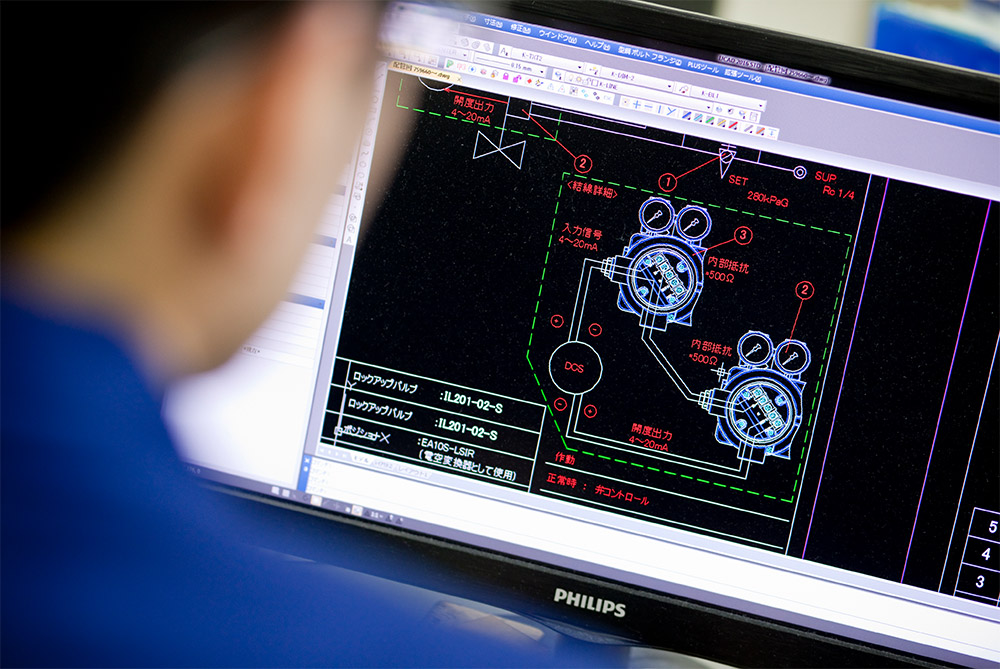

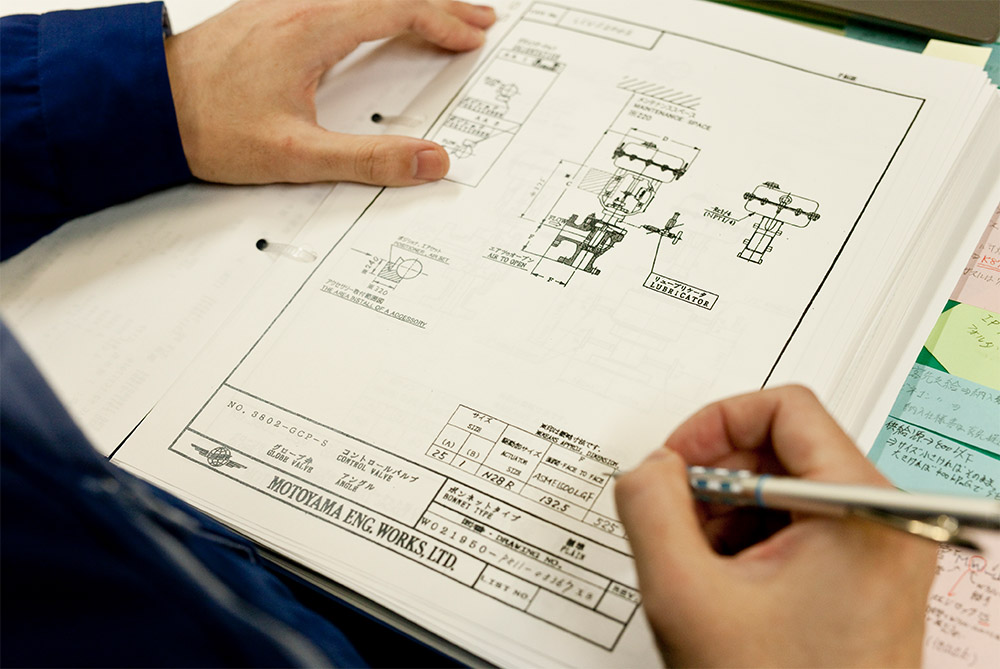

Production at the company is for the most part responsive to made-to-order, except for some product lot production. To respond accurately and quickly to these multiple, diverse requests, we have introduced our Company's own independent production management system. We use advanced technical capabilities and state-of-the-art facilities, and continue to provide high-quality products.

The Ohira Plant is the Company's focal point for promoting even more advanced research and development, and production, in response to the needs of a new age. Here, we have brought together all of the Motoyama technology and various know-how to date, to build the "CIM System" for sharing and synthesizing information everywhere from sales to production, and contributing greatly to total productivity improvement through submission of quick sizing and estimates in response to customer needs, and economies of time and expenses in flexible production systems, etc.

In addition, this is a high amenity plant where employees can work in safety and comfort, with enthusiasm and pleasure, and also is a local reconciliation plant that contributes to the happiness of local society.

| Name | Quantity | Specification |

|---|---|---|

| Computerized Numerical Control Machine |

17 | Tuming Center Robot |

| Machining Center | 3 | |

| Drilling Machine | 4 | 140 x 630(mm) Table Scale |

| Lathes | 26 | |

| Vertical Lathe | 6 | 700 x 2000(mm) Table Scale |

| Milling Machines | 4 | |

| Drill Presses | 36 | Dia. 0.1~75(mm) |

| Planers | 3 | |

| Tapping Machines | 11 | |

| Welding Machines | 45 | Automatic Welding Machine |