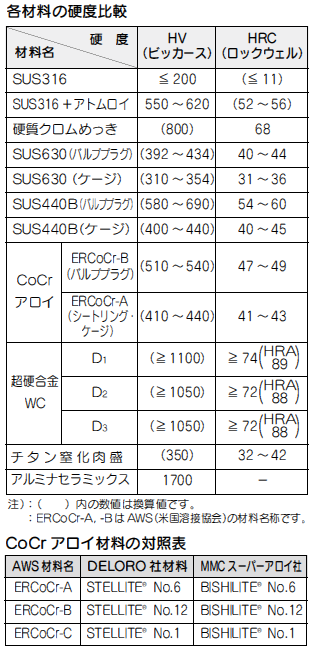

Trim Materials

Trim in control valves refers to valve plugs, cages, sheet rings, and valve stems, and constitute the heart of the valve. Since the trim receives changes in the fluid energy when in direct contact with fluids, this is the part hit with the greatest effects of cavitation or flashing.

Therefore, there is a need to select materials with a higher grade than the normal for main body materials.

Materials used as standard include SUS304 (SCS13A) and SUS316 (SCS14A) stainless steel.

When the fluid differential pressure/temperature is high, when there is concern about cavitation or flashing, etc., or when the fluid includes slurry, a hardening process is necessary.

➔ Types of Hardening Materials / CoCr Alloy Deposited Hardening

◎ Types of Hardening Materials

■ Heat Treatment Hardening

Precipitated Hardening Material SUS630 Stainless Steel: Corrosion resistance is around the same level as SUS304, and the usage temperature limit is -20°C to +400°C.

SUS440B Stainless Steel: The usage temperature limit is -20°C to +400°C.

■ Deposited Hardening

CoCr Alloy: These are Co, Cr, and W alloys, and characteristics are maintenance of hardness and strength even at high temperatures, resistance to oxidation, and a relatively low friction coefficient, etc.

Therefore, these are optimal as deposited hardening materials for high temperatures and high pressure differentiation. (While CoCr alloy was in the past listed under the Stellite® name, this has been changed to the ordinary name.)

■ Chemical Hardening

Atomlloy: W, Mo, Cr, Co, V, and Ti, etc., are diffusion-penetrated at high temperature into the surface of a metal, to form an ultra-hard allow layer. The inner layer is left with the physical characteristics (toughness, other) of the parent material while improving the following properties of the surface layer only.

1. High hardness

2. Wear resistance

3. Seizure resistance

However, since the surface layer alloy includes a carbide, it is used in area that are not strong alkaline or strongly acidic.

■ Hardening due to Thermal Spray

Ceramic Spray: Ceramic (Al2O3) is sprayed onto the body inner surface to form a ceramic layer, dramatically improving the wear resistance.

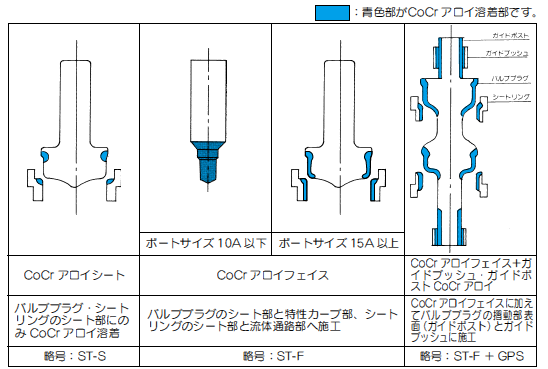

◎ CoCr Alloy Deposited Hardening

The trim valve seat surface demands high corrosion resistance and wear resistance. To satisfy these severe conditions, one ordinary method is to implement deposition of dissimilar metals and surface hardening of the valve seat surface, and the representative metal is CoCr alloy (Co-Cr alloy).

The CoCr alloy hardness is extremely high, and it also features superior corrosion resistance and wear resistance, as well as no decline in hardness even when in a red-hot state. Therefore, it is an essential metal for valve seat deposited materials used in power plants/chemical plants, etc., where temperatures and pressures are becoming progressively higher.

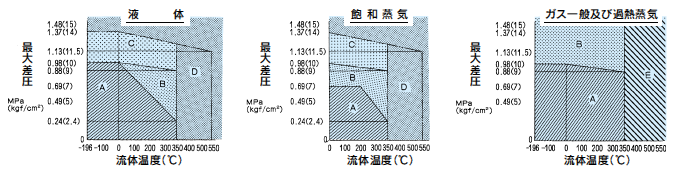

The diagram below shows the metric required for implementation of the CoCr alloy in globe valves for the NO. 3800 Series.

A: CoCr alloy unnecessary B: CoCr alloy sheet (ST-S) C: CoCr alloy phase (ST-F)

D: CoCr alloy phase + guide bush/guide post CoCr alloy (ST-F + GPS)

E: CoCr alloy sheet + guide bush/guide post CoCr alloy (ST-S + GPS)

1. The On-Off valve seat, and the valve seat for completely closed (T.S.O.) slot ring control, use the process at the CoCr alloy or higher.

2. For flashing fluids, the process is at the CoCr alloy phase or higher.

3. Regardless of the fluid type, at +350°C or higher, the CoCr alloy process is performed for the guide bush and guide post.

4. In saturated vapor, if P1 = 0.7 MPaG (7 kgf/cm2G) or higher, the process is at the CoCr alloy sheet or higher.

5. In the flashing and cavitation service, and in saturated vapor, SUS440B is optimal within a temperature range of -20°C to +400°C.

6. The hardening standards for the rotary valve and cage valve will be different. For details, see the respective product catalogs (PDF).